Reasons to Choose

FeRAM-embedded RFIDs

RAMXEED develops and manufactures RFID LSIs in the 13.56MHz HF band. The greatest feature of these RFIDs is that they are equipped with ferroelectric memory (FeRAM). Taking advantage of the high-speed writing and high read/write cycle endurance characteristics of FeRAM, these RFIDs enjoy widespread use in the FA and medical fields, both in Japan and internationally, as high-capacity data carrier type passive RFID LSIs. We also develop and manufacture RFIDs in the 860–960MHz UHF range, offering a diverse product lineup.

Six Reasons to Choose

FeRAM-embedded RFIDs

FeRAM-embedded RFIDs

1.Improved processing speed

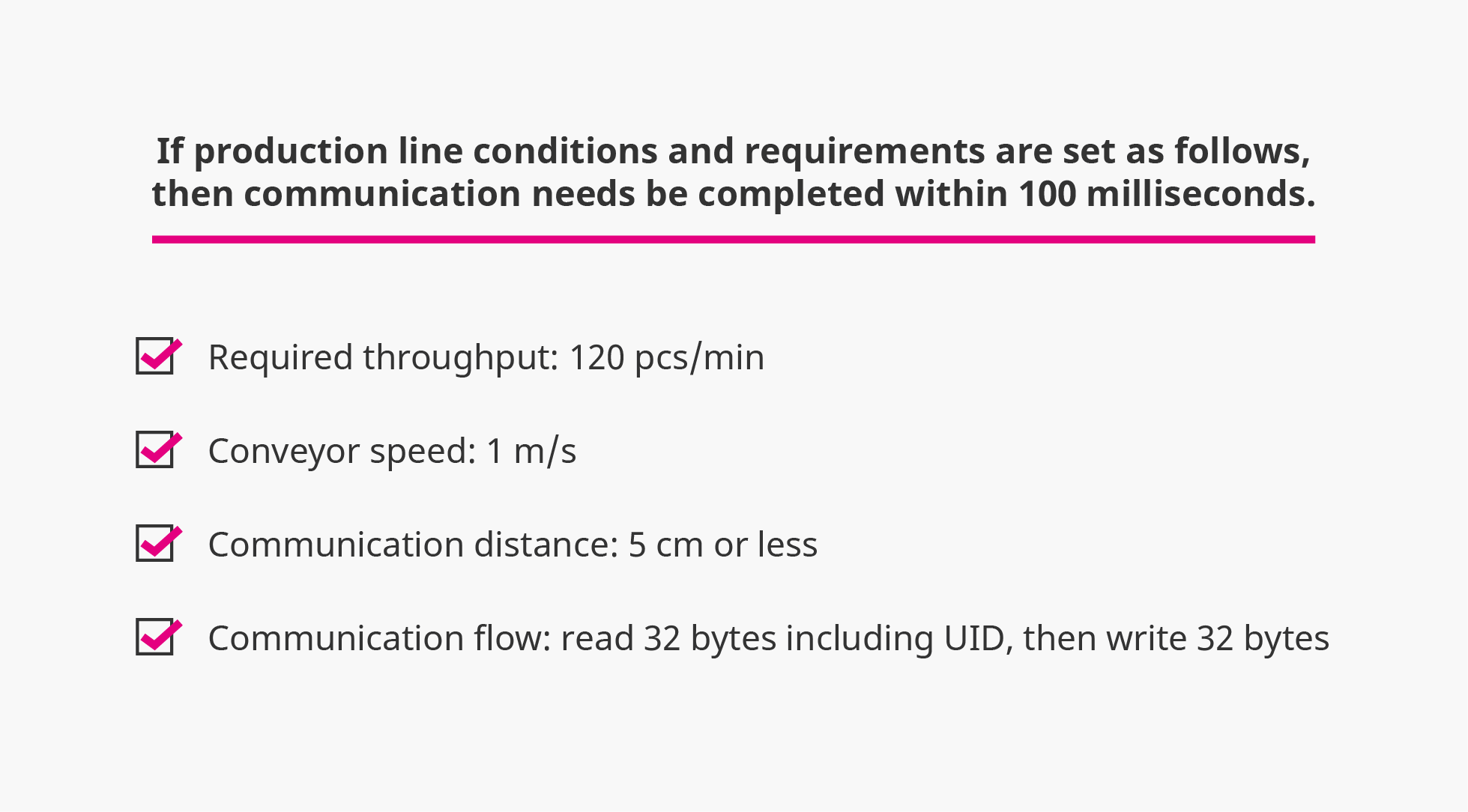

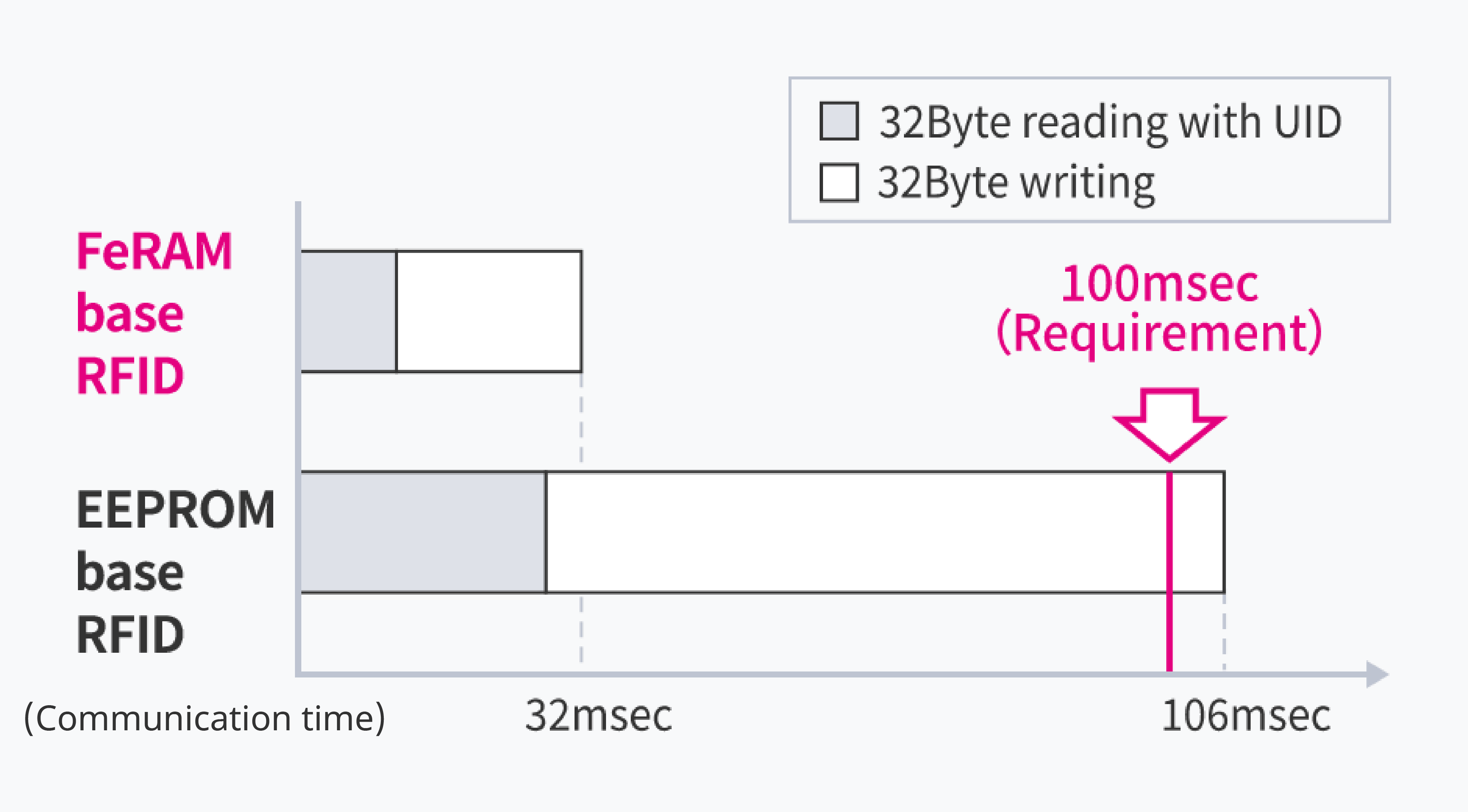

FeRAM can improve data processing speed due to its fast data writing speed and high data retention capabilities. As factories become increasingly automated, accurate and efficient operations will become a key factor in improving productivity.

Achieving high throughput in FA manufacturing processes requires data recorded during the manufacturing process to be written to RFID tag memory at high speed. EEPROM-embedded RFID tags have a slow memory write speed, making them unsuitable for high-throughput production processes.

FeRAM has a very fast write speed compared to other types of non-volatile memory (such as EEPROM). This shortens write times and makes it possible to use FeRAM-embedded RFIDs for high-throughput production line applications.

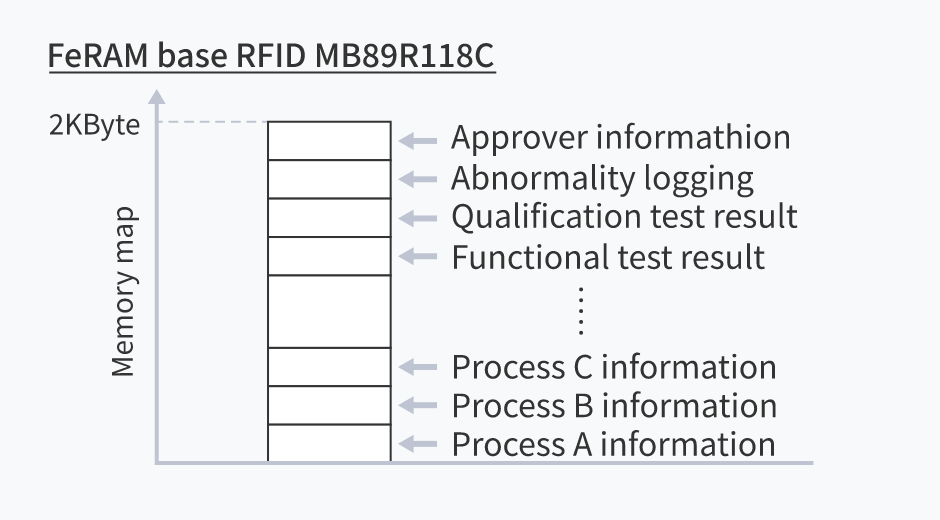

2.Built-in high-capacity memory

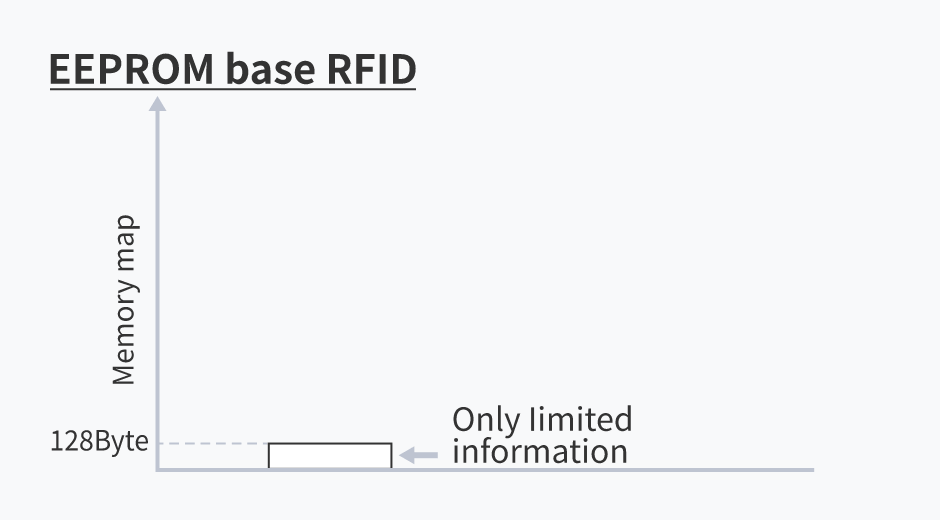

The high speed write processing of FeRAM-embedded RFID tag LSIs has enabled a high memory capacity of 8KB. Using data carrier type passive RFID LSIs for factory automation (FA) enables optimal solutions with high memory capacity and high write speeds.

FA manufacturing processes require updating and storage of large amounts of data such as product information, setting parameters, process histories, and inspection data in real time. However, RFID tags with EEPROM have a slow memory write speed, so it is not possible to update and store large amounts of data in real time.

FeRAM has a very fast write speed compared to other types of non-volatile memory (such as EEPROM). This makes it possible to create RFID tags with high memory capacity and record data accurately in real time.

3.Stable communication distance

Due to the low power consumption of FeRAM memory, the communication distance of write operations is the same as that for read operations. On the other hand, in RFIDs with EEPROM memory, the communication distance for write operations is about half that for read operations. FeRAM has low write power consumption and high data retention capabilities, which enable it to reliably store important data, even in unstable situations such as wireless communication.

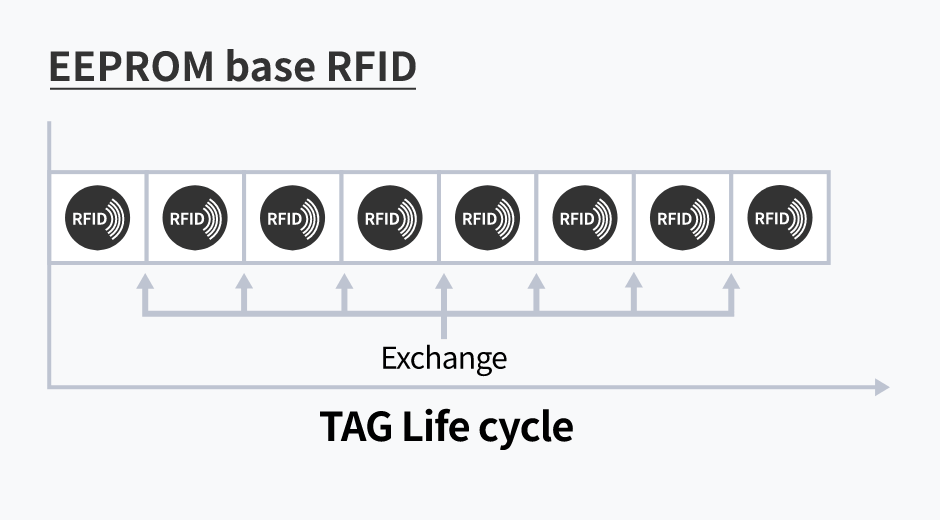

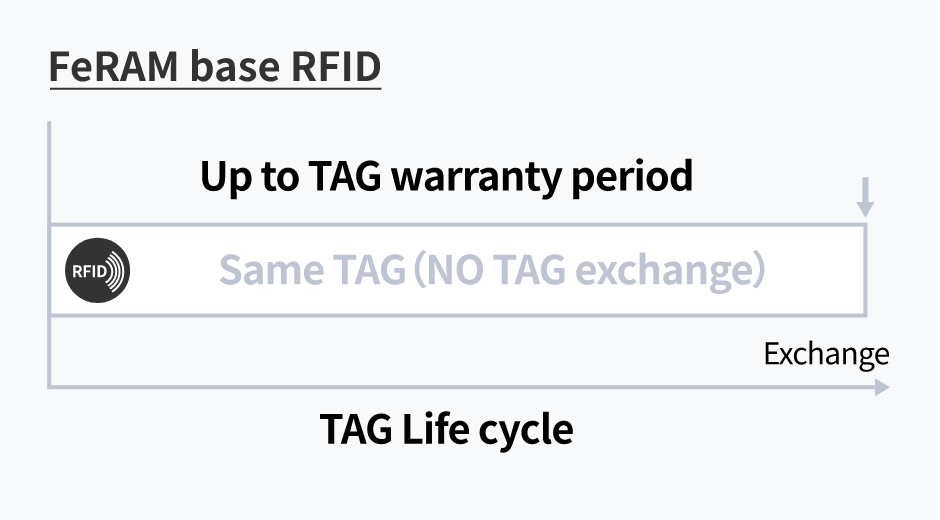

4.High-frequency rewrite capable

FeRAM has a very high number of rewritable cycles, making it highly durable even when used in factory automation (FA) environments with frequent data updates. This guarantees stable operation over a long period, and reduces the cost and effort of maintenance. This feature is expected to improve the efficiency and reliability of manufacturing processes at FA sites.

FA manufacturing processes require RFID tags to have high rewrite endurance when used repeatedly. Conventional EEPROM is limited to one million rewrite operations, and is not suitable for the FA field, which requires fast and frequent rewrites.

FeRAM has high rewrite endurance, which guarantees long-term usability of RFID tags. FeRAM (short for Ferroelectric Random Access Memory) maintains stable performance even during the RFID tag warranty period due to its excellent rewrite endurance. This enables companies to achieve long-term, reliable data retention and reduce the frequency of maintenance and replacements.

* Condition: Write RFID data to the same address once every minute.

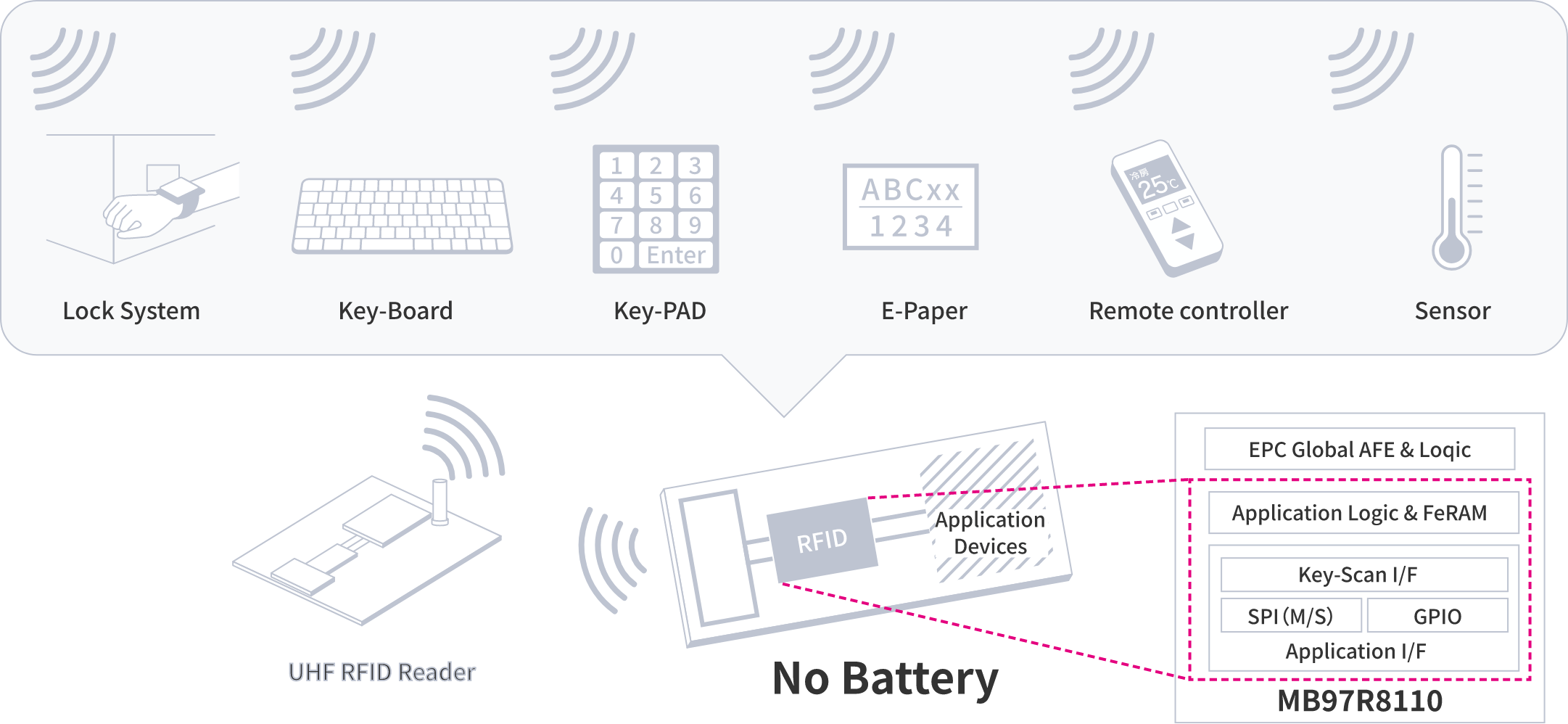

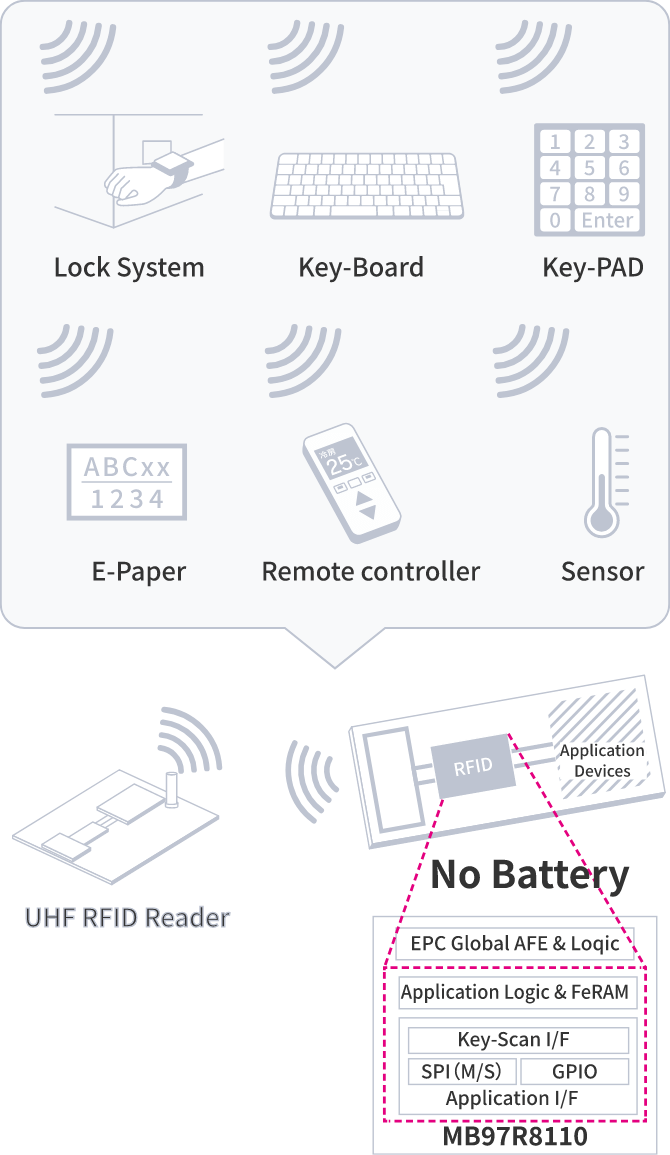

5.Battery-free operation capable

FeRAM has excellent low power consumption when writing, making it suitable for battery-free applications. By embedding the circuitry necessary to drive external devices in conventional RFID LSIs, various power-free and wireless applications can be achieved. This makes it possible to reduce the cost and effort of maintenance, such as battery replacement. This feature enables efficient and economical production management and greatly improves product competitiveness.

6.Excellent radiation resistance

FeRAM has excellent radiation resistance that allows it to retain data even when exposed to gamma rays and electron beam sterilization. This allows FeRAM-embedded RFIDs to greatly increase the efficiency of administrative tasks and improve traceability in the medical and pharmaceutical fields. This feature enables full traceability management with RFID tags in all processes, from product production to disposal. It also allows accurate tracking of product histories, improving quality control and safety.