Applications

Case Study; FeRAM in HMI for Robots in Factory Automation

Dramatic Reduction of Downtime at FA Sites:

FeRAM's high-speed write enables fast recovery from a momentary power loss during operation

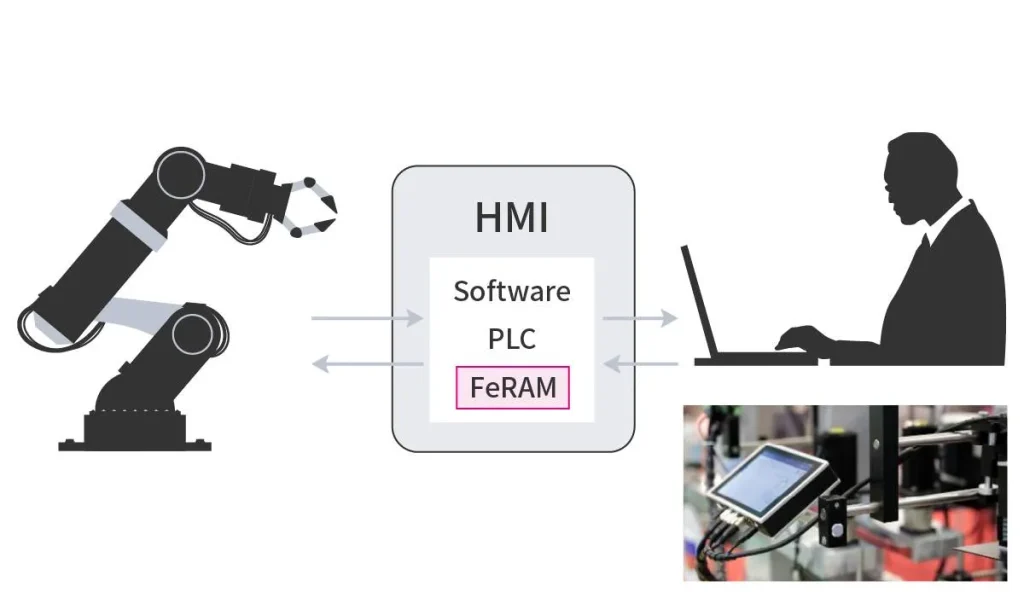

FeRAM is also used in the HMI (Human Machine Interface) of robots for factory automation in factories. High-speed data writing constantly records parameters and setting information of the robot arm, contributing to shorter recovery time even during production line stoppages due to power failure or other accidents.

Table of Contents

Features and Advantages of FeRAM

As factories become increasingly automated, accurate and efficient robot operation is key to improving productivity. In particular, various setting parameters, such as the angle and strength of the robot arm, must be accurately managed and stored. FeRAM (Ferroelectric Random Access Memory) is the focus of attention here, as its high data write speed and high data retention capability ensure that important data can be reliably stored even in unexpected situations such as power failure.

Reasons for Adoption of FeRAM in HMI for Robots in Factory Automation

High-speed data writing

FeRAM has a very high write speed compared to other non-volatile memory (NVM). This makes it possible to update and store configuration parameters such as the angle and strength of the robot's arm in real time. This allows the robot's movements to be controlled quickly and accurately.

Highly reliable data retention

In the event of a power failure or unexpected system downtime in the factory, FeRAM retains data with high reliability. This includes not only configuration parameters, but also dynamic state information such as the robot's current position, speed, and sensor data. This allows the previous state to be restored immediately after a restart, minimizing downtime and helping to maintain productivity.

Durability and Long Life

FeRAM has an extremely high write endurance, making it highly durable even in factory automation environments where frequent data updates are performed. It guarantees stable operation over a long period of time, reducing maintenance labor and costs.

Case Studies

An advanced manufacturing plant uses FeRAM in HMI for robots. The factory requires fine motion control of the robot arm, and FeRAM enables rapid writing of setting parameters and reliable data retention.

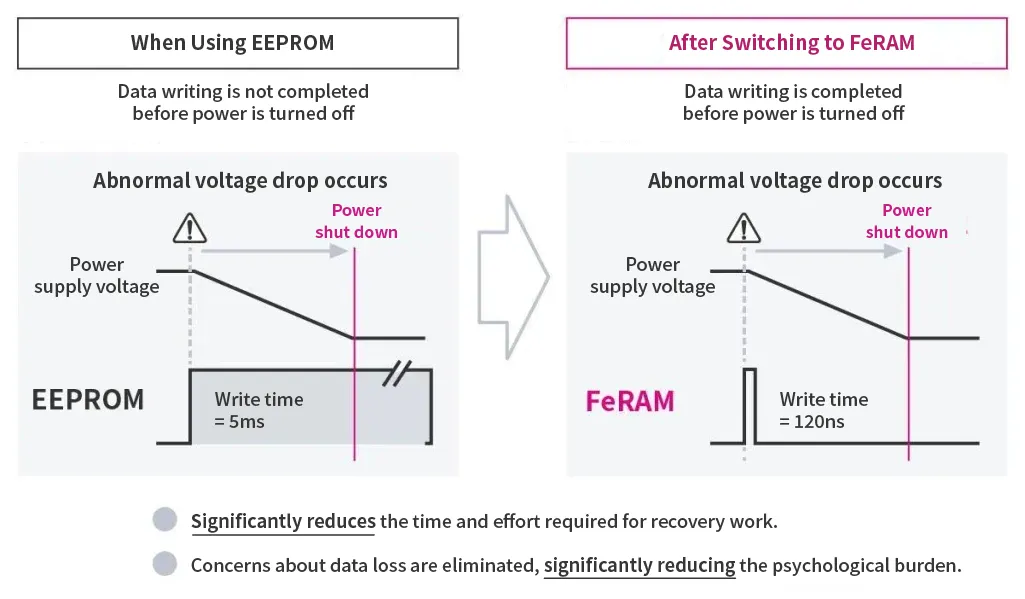

The customer originally used EEPROM, but EEPROM is prone to data loss in the event of power failure or system downtime, and important status information such as robot arm angle, speed, and sensor data was frequently lost. This was a cause of reduced production efficiency, as it was necessary to reconfirm the setting parameters for each arm when the production line was restored.

To solve this problem, the customer began considering the introduction of FeRAM.

After the introduction of FeRAM, high-speed data writing became possible, and setting parameters and status information could be saved in real time. This eliminates the worry of data loss in the event of a power failure, and when the production line is restored, the previous setting parameters and status information are immediately restored, greatly reducing the time and effort required for restoration work.

The psychological burden is greatly reduced because the operator no longer has to worry about data loss of parameter information necessary for the equipment. This allows operators to concentrate on production work with peace of mind and improves overall production efficiency.

Conclusion

With FeRAM, HMIs of robots for factory automation can manage data faster and more reliably. Rapid data recovery in the event of power failure and long-life, highly durable memory technology will greatly contribute to improved production efficiency. FeRAM will continue to play an important role in the field of factory automation.

Typical Adopted Part numbers

- MB85RS256B : 256Kbit SPI I/F 2.7~3.6V 33MHz -40~85℃ SOP8

- MB85RS512T : 512Kbit SPI I/F 1.8~3.6V 30MHz -40~85℃ SOP8

- MB85RS1MT : 1Mbit SPI I/F 1.8~3.6V 40MHz -40~85℃ SOP8

- MB85RS2MTY : 2Mbit SPI I/F 1.8~3.6V 50MHz -40~125℃ SOP8/DFN8

- MB85RS4MTY : 4Mbit SPI I/F 1.8~3.6V 50MHz -40~125℃ SOP8/DFN8

Please click here for the data sheet of each product type.