Applications

Case Study; FeRAM in PLC

Don't be afraid of unexpected power loss:

PLC with FeRAM that saves data immediately before a momentary power loss to ensure recovery

Table of Contents

Role of a PLC (Programmable Logic Controller)

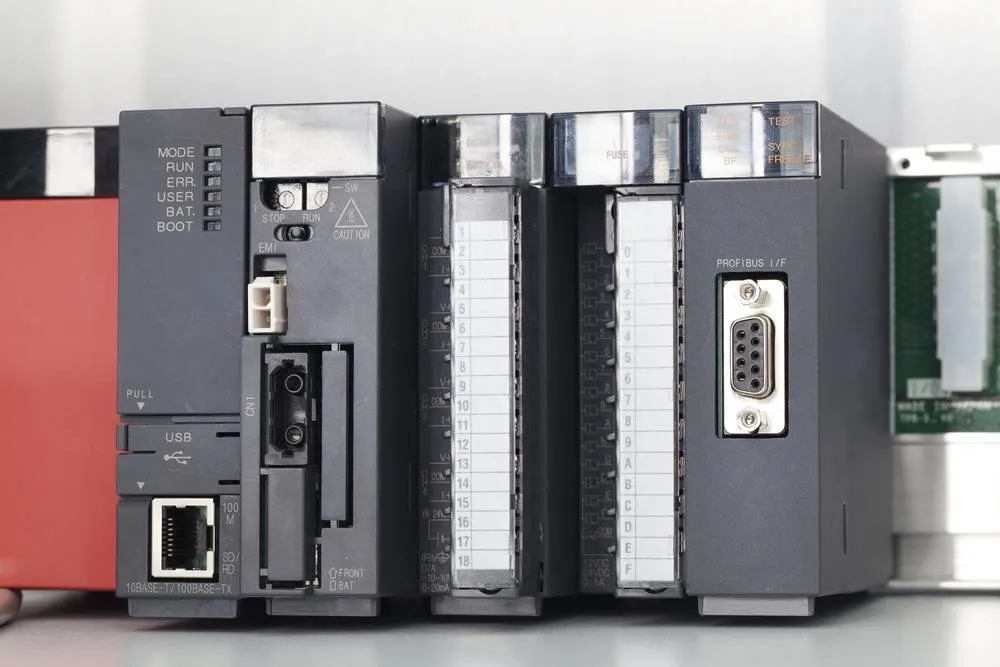

Programmable logic controllers (PLCs) enable automation and advanced control of equipment operation in manufacturing lines for automobiles and electrical equipment, factory equipment for semiconductor manufacturing and metal processing machinery, and elevator control.

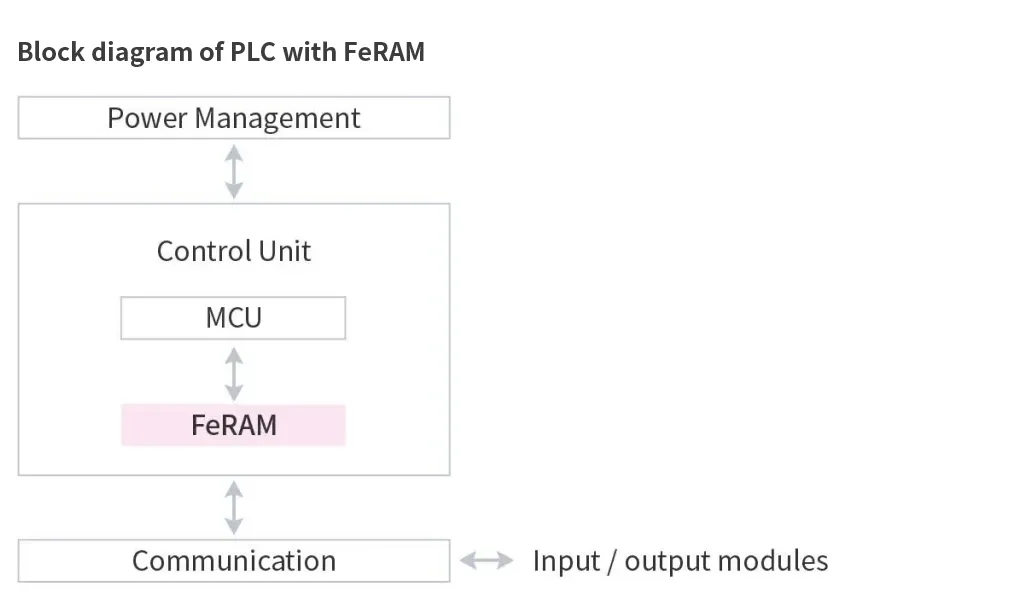

PLCs are sequence control devices that process signals from input devices and control output by integrating with I/O modules. Since PLCs are used on production lines, they must be highly reliable, easy to maintain, and have a long system life. In addition, the superior characteristics of FeRAM (ferroelectric memory) are of great benefit, as it must provide reliable control and safely restart equipment in the event of an unexpected loss of power supply.

FeRAM Features and Benefits

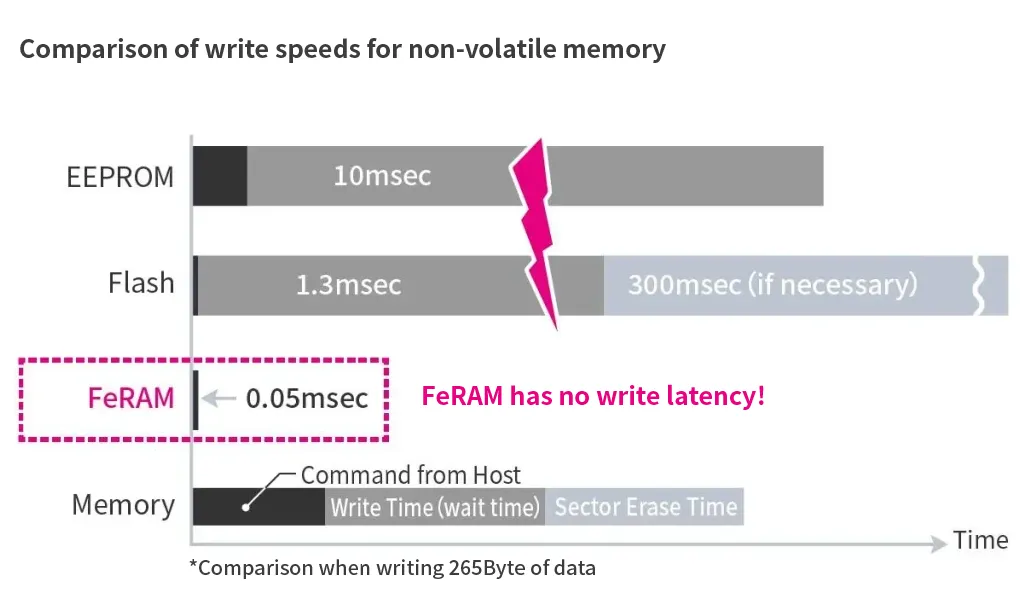

FeRAM is a memory technology with high write speed and high write endurance. Therefore, it offers the following advantages in PLCs.

High-speed data recording:

PLCs need to cope with unforeseen events such as an unexpected drop in system voltage. By rapidly saving control parameters, I/O status, and Run/Stop mode to FeRAM before the system voltage is completely lost, the system can be restarted correctly and the cause of the problem can be traced. Early system restarts help minimize downtime and increase manufacturing equipment uptime, while identifying the cause of the problem helps ease maintenance of PLCs and PLC-connected equipment.

High write endurance:

PLCs require constant logging of control parameters, I/O status, Run/Stop modes, etc., to determine what events were occurring before an unexpected system voltage drop. This ensures reliable operation over the entire long system life.

Data retention:

FeRAM does not lose data in the event of power loss, so safe operation can be resumed immediately after power is restored. FeRAM with guaranteed operation at 125°C has data retention characteristics of more than 10 years at 105°C and can reliably retain data even in harsh environments.

Case study

A leading global manufacturer of factory automation devices such as PLCs, motion controllers, servo motors, and HMIs uses FeRAM in a wide range of products, including PLCs.

The customer's PLCs are expected to be used in harsh environments, and end-users require them to operate reliably even when the power supply is unstable. The customer's PLC must be able to store about 128 KBytes of data such as operation mode and status within a short period of time (several 10 ms) when the power supply voltage drops, and restart the PLC without problems when the power supply voltage is restored.

It was clear that conventional nonvolatile memories such as EEPROM and FLASH memory had slow write speeds and that it would be difficult to achieve specifications that would satisfy the requirements from the end user.

The customer narrowed down its selection to high-speed nonvolatile memory, and FeRAM was selected as a candidate because of its proven track record in the market

The customer has further increased the number of end-users with FeRAM-based products, ensuring its reputation and proven track record in the market.

Summary

In PLCs, FeRAM offers high reliability, ease of maintenance, and long system life due to its fast write speed, high write endurance, and excellent data retention.

Recommended Products

- MS85R4M2TA : 4Mbit Parallel I/F 1.8V~3.6V -40~85℃ TSOP44

- MB85RS4MTY : 4Mbit SPI I/F 1.8V~3.6V 50MHz -40~125℃ SOP8/DFN8

- MB85RS2MTY : 2Mbit SPI I/F 1.8~3.6V 50MHz -40~85℃ SOP8/DFN8

- MB85RS1MT : 1Mbit SPI I/F 1.8~3.6V 40MHz -40~85℃ SOP8/DFN8

- MB85RS512TY : 512Kbit SPI I/F 1.8~3.6V 50MHz -40~125℃ SOP8/DFN8

- MB85RS256B : 256Kbit SPI I/F 2.7~3.6V 33MHz -40~85℃ SOP8