Applications

Example of adoption of FeRAM in measuring instruments (temperature controllers)

Enabling millisecond-by-millisecond temperature control:

Realization of high-speed data writing and long life with FeRAM

Temperature controllers used in manufacturing lines for semiconductors, electrical equipment, molding machines, etc. play an important role in improving product quality, reliability, and productivity through precise temperature control in the manufacturing process.

Table of Contents

Role of Temperature Controllers (Temperature Regulators)

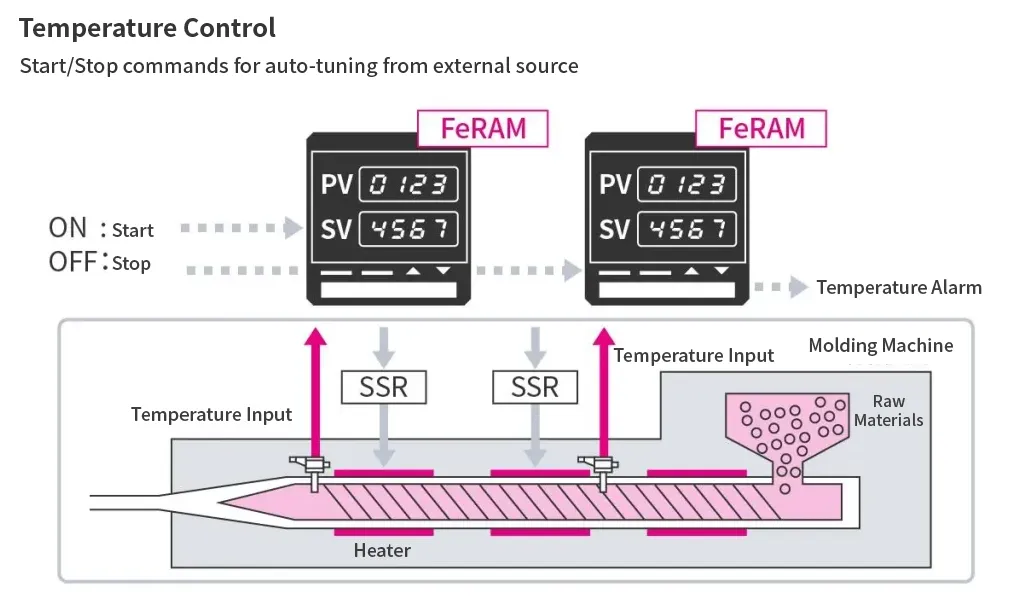

A temperature controller is a device that compares the current measured temperature obtained from a sensor with a target temperature in temperature control of a molding machine, etc., and performs calculations and makes corrections according to the deviation.

Since the temperature controller controls the current value to match the target value, it must reach the target value as quickly as possible. In addition, in the event of a device failure, it is necessary to record realistic temperature changes inside the furnace in order to properly process the device after restoration.

Example of FeRAM installed in a temperature controller

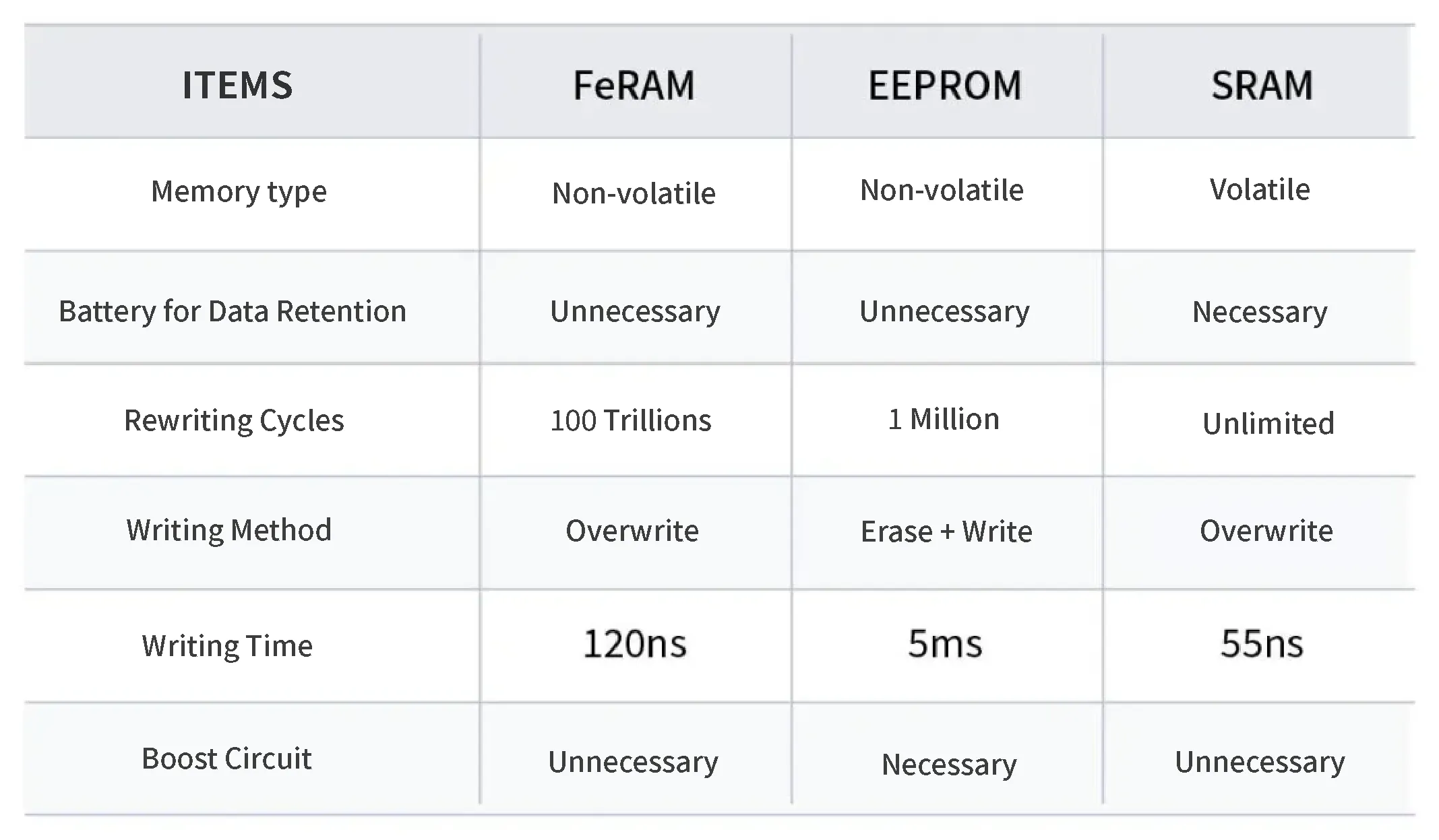

In some cases, FeRAM has been used in temperature controllers because of trouble caused by insufficient performance of the EEPROM that was originally used. Although FeRAM and SRAM met the requirements for rewrite endurance, FeRAM was adopted because FeRAM has the advantage of not requiring battery backup in case of system voltage loss due to failure.

Rapid Recovery from Unexpected Failures

The temperature controller rapidly saves furnace temperature data obtained from the temperature sensor to FeRAM before the system voltage is completely lost, thereby helping to resume production quickly after the system is restored.

High rewrite endurance that enables recording of log data in milliseconds

Raw materials are fed into molding machines, etc., and various controls are performed while compensating for highly accurate temperature changes. This temperature change information must be recorded in memory as log data in milliseconds. Nonvolatile memory requires not only high-speed writing but also rewrite endurance. FeRAM, which is made with the latest technology, can now guarantee rewrite endurance of up to 100 trillion times.

Adoption of FeRAM improves the reliability of products in terms of accuracy and longevity, and also reduces peripheral circuits for the use of batteries and capacitors, contributing to lower development costs for our customers due to its simple circuit configuration.

Summary

In temperature controllers, FeRAM's high-speed write and high rewrite endurance allow customers to not only easily construct measures against powerdowns, but also to acquire highly accurate data in real time, thereby contributing to manufacturing.

Recommended Products

- MS85R4M2TA : 4Mbit Parallel I/F 1.8V~3.6V -40~85℃ TSOP44

- MB85RS4MTY : 4Mbit SPI I/F 1.8V~3.6V 50MHz -40~125℃ SOP8/DFN8

- MB85RS2MTY : 2Mbit SPI I/F 1.8~3.6V 50MHz -40~125℃ SOP8/DFN8

- MB85RS1MT : 1Mbit SPI I/F 1.8~3.6V 40MHz -40~85℃ SOP8/DFN8

- MB85RS512TY : 512Kbit SPI I/F 1.8~3.6V 50MHz -40~125℃ SOP8/DFN8

- MB85RS256B : 256Kbit SPI I/F 2.7~3.6V 33MHz -40~85℃ SOP8