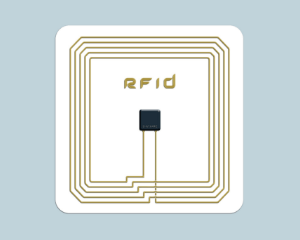

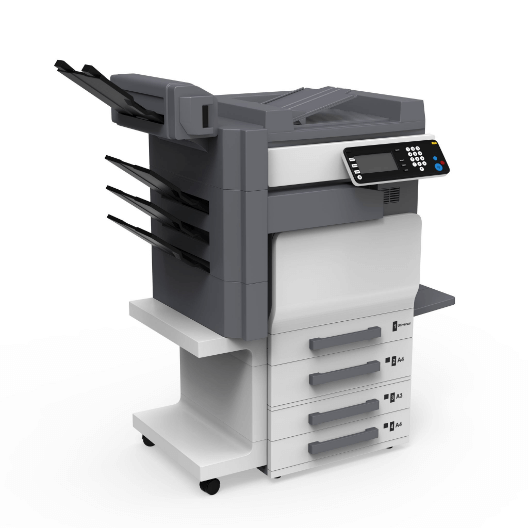

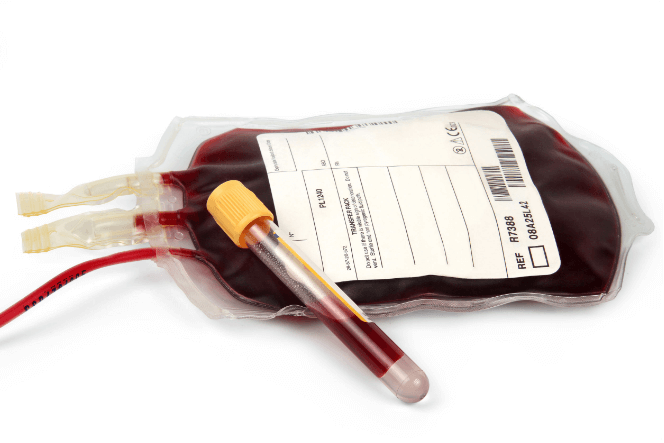

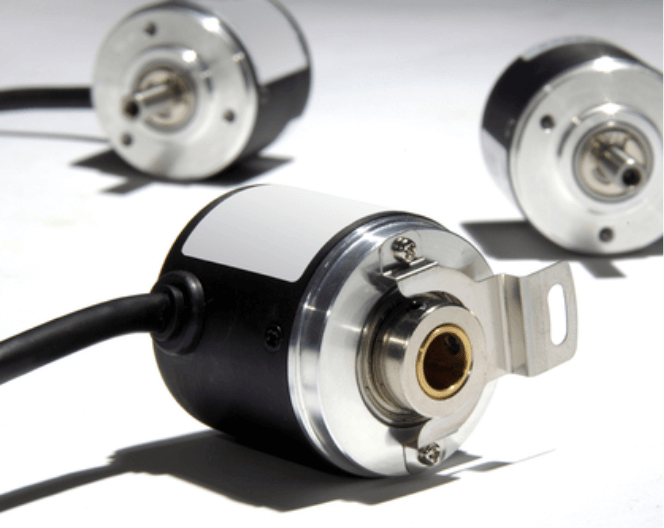

Customers wish to protect products from counterfeiting, and protect their safety and reliability.

Reasons to Choose FeRAM

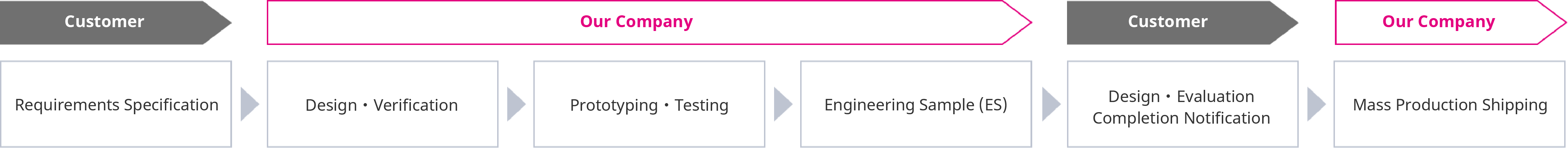

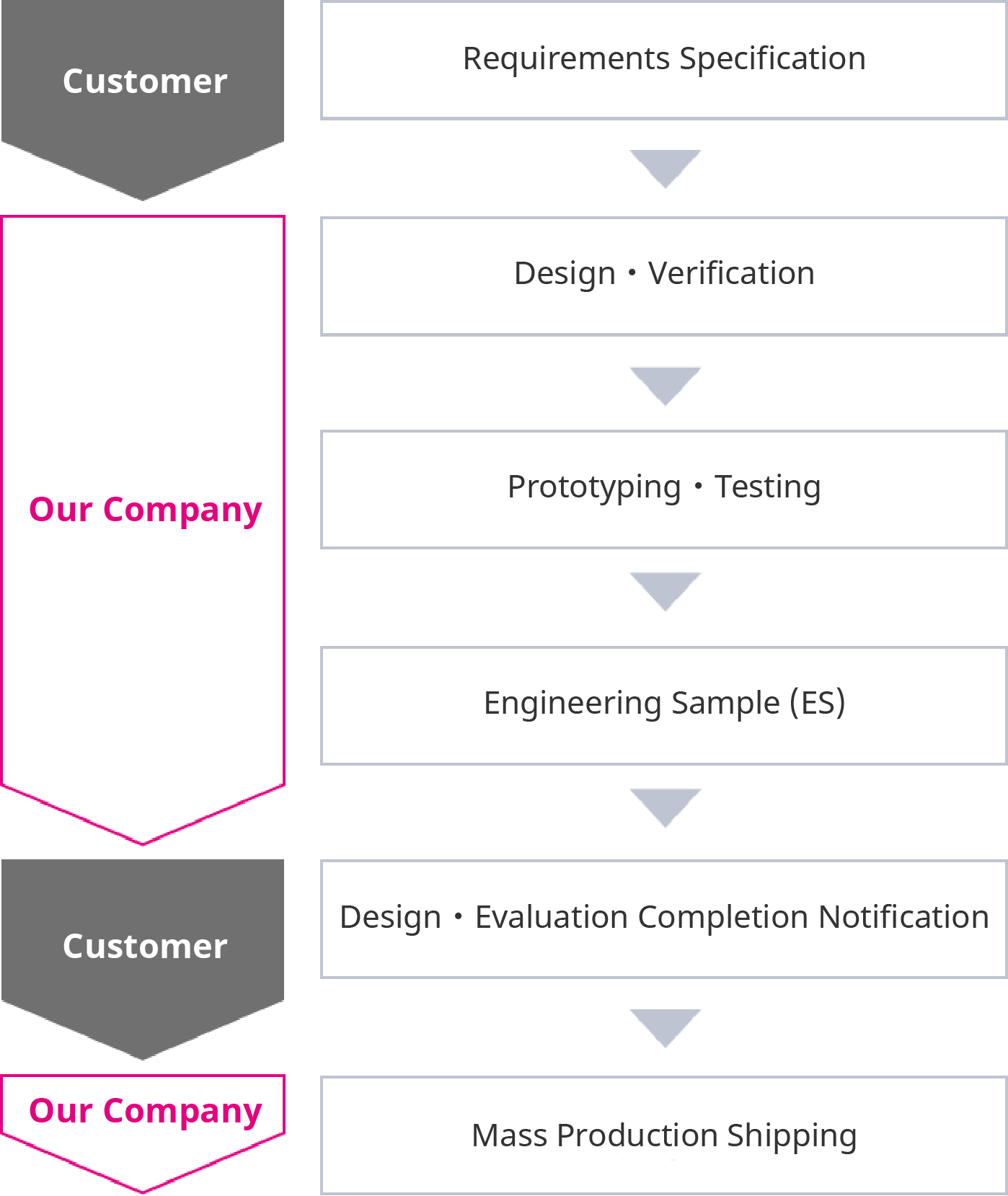

RAMXEED’s unique crypto-less authentication has high security strength because there is no key information to be stolen, and protects customer products from the threat of counterfeiting. We deliver ICs that can be used for a long time with peace of mind, and reduce the burden of development placed on our customers.